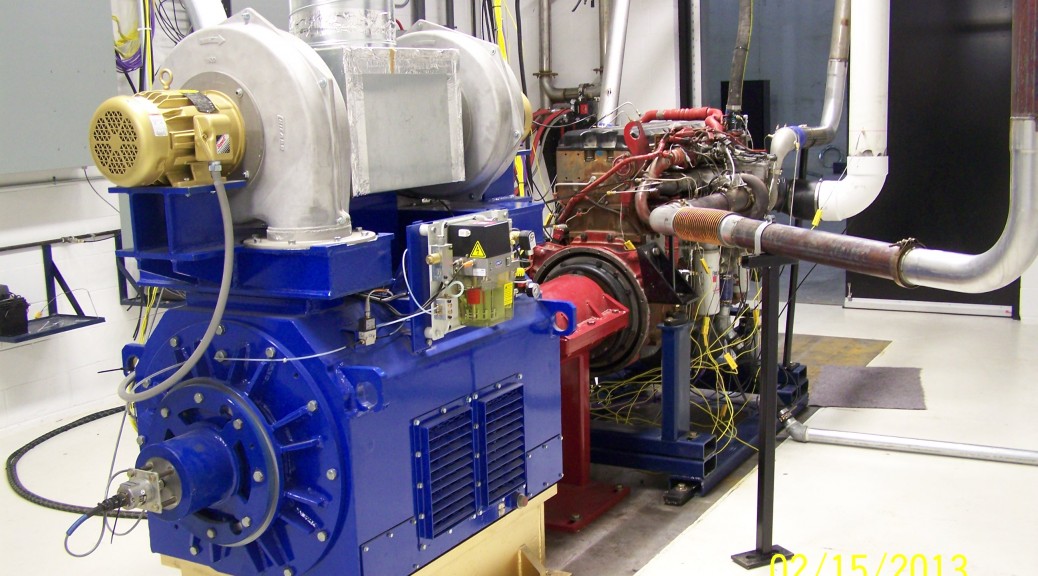

The AEI facilities, which include twenty six engine dynamometer and component development cells, are uniquely designed to provide a research and development environment in support of a breadth of diesel/gasoline/natural gas engines and/or vehicle development programs. Numerous engine development services are offered, ranging from endurance development to ratings development for optimum performance and emissions compliance. Engineering staff can provide custom engine testing cycles that are written to support cooperative development programs and more rapidly iterate toward a robust working solution.

Featured Capabilities

- 26 engine dynamometer and component development cells

- Ambient Air Temperature Control down to 70F

- Emissions Analyzers

- FTIR Analyzers with 5Hz sampling

- Particulate Matter (PM) Measurement – 1065 and tier IV

- Smoke Measurements

- Lubricant Oil Soot Measurements

- High Speed Data Acquisition – real time cylinder pressure and heat release up to 96 channels

- Loaded cold start and cold operation

- Dynamic control of intake air and exhaust restrictions/pressures

- Rapid response charge air, coolant, and fuel temperature control

- 24 hour continuous support

- Automated data acquisition

- Remote real-time data retrieval with customer logins

- HEPA filtered, temperature and humidity controlled combustion air

- Automated transient cycles or steady state operation

Super/Altitude Development Cells

The AEI Super Cell provides a stable and repeatable location for transient development of engine systems at altitude. Traffic, weather, and road conditions make it impossible to repeat the exact same driving cycle in an on-road vehicle in the mountains. As engines are being developed with more complex air handling, fuel systems, and integrated aftertreatment exhaust systems, the frequency of required development in the mountains continues to escalate. Engine sociability with smoke during transient operation has also become a large problem with the multi-dimensional air handling systems involving modulated EGR and VG turbocharger. In order to provide useful information about smoke visibility and color, an exhaust stack mounted remote camera can be viewed right at the development cell console.

AEI’s Super Cell is uniquely configured to simulate altitude conditions, with controlled intake air supply sources that are maintained isobarically with the exhaust out pressure. The majority of other facilities’ engine test cells that offer “altitude” capability are only able to maintain exhaust out pressure, and then create a simulated intake supply pressure by increasing intake restriction. Then for transient operation, that intake restriction valve must be modulated to attempt to achieve a certain pressure level. AEI’s isobarically controlled intake and exhaust systems eliminates the need for feed forward control of the intake restriction, therefore, providing a better altitude environment for transient development requirements.

Super Cell Capabilities

- Up to 14,000 feet altitude simulation for steady state and transient development

- Altitude is maintained during transient cycle

- Temp to -35ºC at startup

- Driving simulation

- Continuous raw emissions measurement and smoke

- Temperature controlled intake air from 110ºF to below 32ºF

- Temperature controlled CAC out down to 40ºF

- Humidity controlled intake air at 77ºF and 75 gr/lb

Emissions Measurements

AEI offers a comprehensive suite of tools and technologies to accurately monitor and analyze exhaust emissions. Our state-of-the-art equipment and methodologies ensure precise measurements across a wide range of parameters, supporting the highest standards of environmental compliance and research.

FTIR Analysis

Our Fourier Transform Infrared (FTIR) spectroscopy, provided by MKS, offers exceptional sensitivity down to parts per billion (ppb). These FTIR systems are capable of handling samples with up to 40% water content and can measure over 30 different gases. With calibrations available for multiple fuels, our FTIRs provide accurate and versatile gas analysis for a variety of applications.

5-Gas Emissions Rack

Our 5-gas emissions rack delivers rapid response times of less than 10 seconds, providing quick and reliable measurements of critical emissions parameters. The rack covers a broad range of measurements, including:

- NO (Nitric Oxide): Up to 3,000 ppm

- CO (Carbon Monoxide): Up to 10,000 ppm

- CO2 (Carbon Dioxide): Up to 20%

- HC (Hydrocarbons): Up to 30,000 ppm

- O2 (Oxygen): Up to 25%

Smoke Measurement

We utilize advanced AVL technology for smoke measurements, with models AVL 415, AVL 439, and AVL 497.

These instruments provide detailed and accurate assessments of particulate emissions, ensuring that our measurements meet the stringent requirements of various regulatory standards.

Multiplexer Capability

Our emissions measurement system features multiplex capability, allowing us to simultaneously monitor up to 30 separate locations with one emissions rack. This feature is crucial for comprehensive testing and analysis, providing a holistic view of emissions across multiple points in your system.

Natural Gas Measurements

For incoming natural gas measurements, we use ONGA technology. This system ensures accurate analysis of natural gas properties, essential for optimizing combustion processes and verifying fuel quality.

Fuel Options

At AEI, we offer several fuel options for all testing, including gasoline, diesel, natural gas, ethanol, propane, and custom-blended fuels. Our state-of-the-art facility is equipped to handle your unique testing requirements, ensuring that each fuel type meets specific performance and compliance standards.

One of our specialized capabilities is the ability to mix sulfur into fuel to precise levels. This enables us to simulate various real-world conditions and meet the specific needs of your testing protocols. To guarantee accuracy, we have an on-site laboratory dedicated to measuring the sulfur content in fuels, providing you with reliable data for your analysis.

Whether you’re developing new fuel formulations, evaluating fuel performance, or ensuring regulatory compliance, AEI is ready to support your testing needs. Our team of experts is here to help you achieve your goals with precision and confidence.