Engine Component Development - AEI has designed, built, and installed a variety of stands for component development and evaluation. These development...(click for more info)

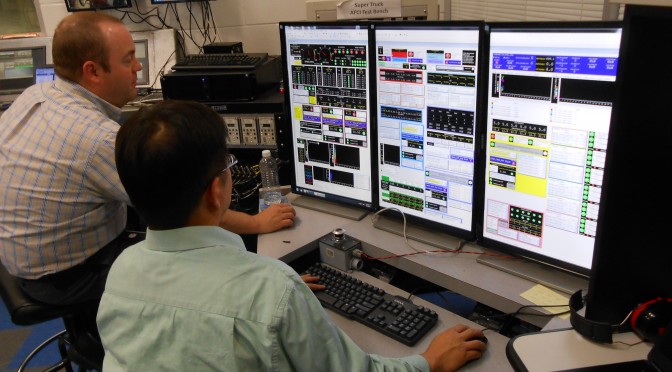

Analytical Engineering, Inc. offers development of prototype hardware in our test cells utilizing engine testing methods that include both industry standard and custom developed cycles. AEI has designed, built, and installed a variety of stands for component development and evaluation. These development rigs are operated and monitored according to development plans cooperatively developed with the customers. HALT and HASS development is available as well as durability bench development, environmental development, thermal development and altitude development. Data acquisition is almost limitless at AEI due to our in-house electrical engineering and controls software.

- Custom-designed rigs for rapid, cost-effective component development

- Simulation of temperature, pressure, flow rates and vibration conditions for component development

- Cooperative rig design and test planning

- In-house rig construction using AEI engineering and skilled fabrication resources

Engine Thermostat Development - A thermostat is a good example of a component that may be cyclically developed without the need for installation in...(click for more info)

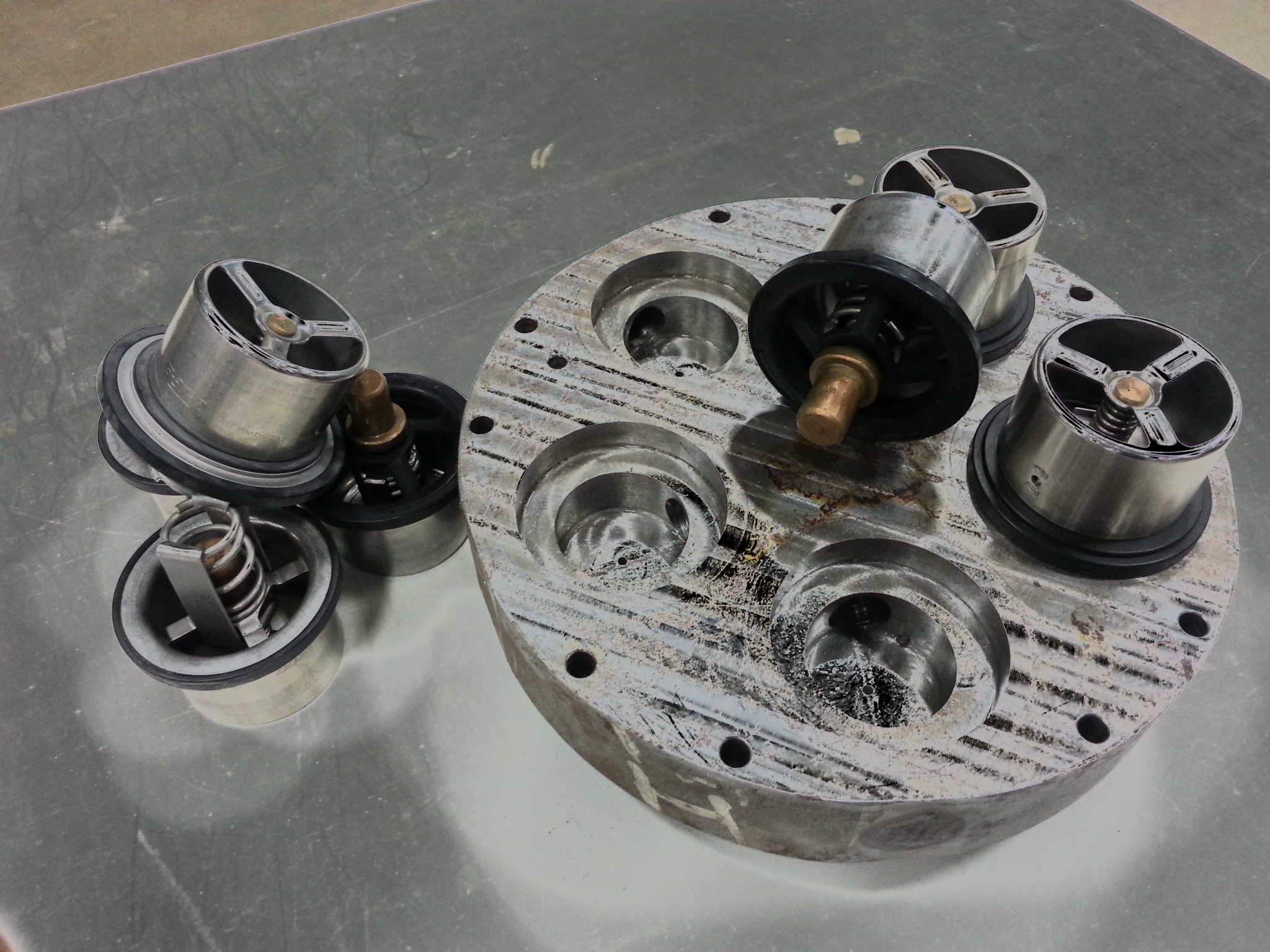

A thermostat is a good example of a component that may be cyclically developed without the need for installation in an engine. Many thermostats can be simultaneously developed with a custom designed development stand at a cost significantly less than an equivalent engine development. AEI has designed and constructed a dedicated development rig for coolant thermostats. This development stand has been utilized several times to validate new suppliers or design changes by thermally cycling five thermostats through at least thirty thousand repetitions, while stopping the development to check for length of stroke at a pre-determined number of cycles throughout the validation process. In this instance, a cycle is defined as fully opening the thermostat with 220°F fluid, then decreasing the fluid temperature to 160°F to close the thermostat.

A thermostat is a good example of a component that may be cyclically developed without the need for installation in an engine. Many thermostats can be simultaneously developed with a custom designed development stand at a cost significantly less than an equivalent engine development. AEI has designed and constructed a dedicated development rig for coolant thermostats. This development stand has been utilized several times to validate new suppliers or design changes by thermally cycling five thermostats through at least thirty thousand repetitions, while stopping the development to check for length of stroke at a pre-determined number of cycles throughout the validation process. In this instance, a cycle is defined as fully opening the thermostat with 220°F fluid, then decreasing the fluid temperature to 160°F to close the thermostat.EGR Cooler Durability - AEI designed and built a development stand that simultaneously develops four EGR coolers. These coolers were subjected...(click for more info)

AEI designed and built a development stand that simultaneously tests four EGR coolers. These coolers were subjected to temperature extremes on the exhaust gas and coolant sides, simulating thermal expansion, contraction, and pressures. The coolant and gas flow rate could be modulated to achieve different heat transfer scenarios. This stand has been utilized to develope EGR coolers up to 50,000 thermal cycles. Temperature, pressure, and flow rate information was recorded at one hertz so that the performance could be tracked over time.

AEI designed and built a development stand that simultaneously tests four EGR coolers. These coolers were subjected to temperature extremes on the exhaust gas and coolant sides, simulating thermal expansion, contraction, and pressures. The coolant and gas flow rate could be modulated to achieve different heat transfer scenarios. This stand has been utilized to develope EGR coolers up to 50,000 thermal cycles. Temperature, pressure, and flow rate information was recorded at one hertz so that the performance could be tracked over time.