Electrification Development

Analytical Engineering, Inc. offers a unique combination of capabilities to meet customer-specific development requirements for electric vehicle components and subsystems. As the global push for fuel economy and greenhouse gas reductions drove OEM’s to pursue electric powertrain components, AEI added capabilities to support the evaluation and development of electrification hardware quickly and cost effectively. We have provided R&D environments for electric subsystems alone and in combination with engine/hybrid systems. With experienced engineering, machining, and fabrication resources on-site, we are able to get prototype parts prepared for testing quickly to accelerate the design process.

Featured Capabilities

- 20 Test cells with motoring dynamometers

- 2 Drive-in temperature chambers with -60F – 120F capability

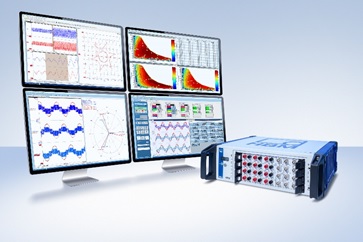

- 9 Channel HBK Power Analyzer with 2 MHz acquisition speed

- Multiple battery simulators

- 24-hour continuous support

- Automated data acquisition

- Automated transient cycles or steady state operation

- Remote data retrieval with customer logins

Battery Development

AEI has worked collaboratively with OEM and component customers to evaluate and refine vehicle battery design at the cell, module and pack level. We have experience with performance and cycle testing, pack assembly and installation of battery packs into test vehicles in our vehicle engineering center. We have installed customer chargers on site to support extended vehicle testing. Our technical staff, with a diversity of experience, works closely with the customer to identify and solve problems as they occur so delays are minimized. We have the ability to design custom electronic and software solutions to support your project and AEI’s internal machining and fabrication resources allow us develop and implement solutions in hours rather than weeks.

Electric Drive Systems

AEI has added bi-directional battery simulators for testing inverters and motor/generators for hybrid vehicles. Our test cells have motoring dynamometers to motor or load the device under test to simulate the full range of operating conditions. AEI technical resources have designed cooling and heating circuits, custom hardware components, and measurement equipment to meet customer-specific test requirements. Our ability to quickly fabricate parts on-site allows customers to react to unforeseen product issues or delays and remain on schedule.